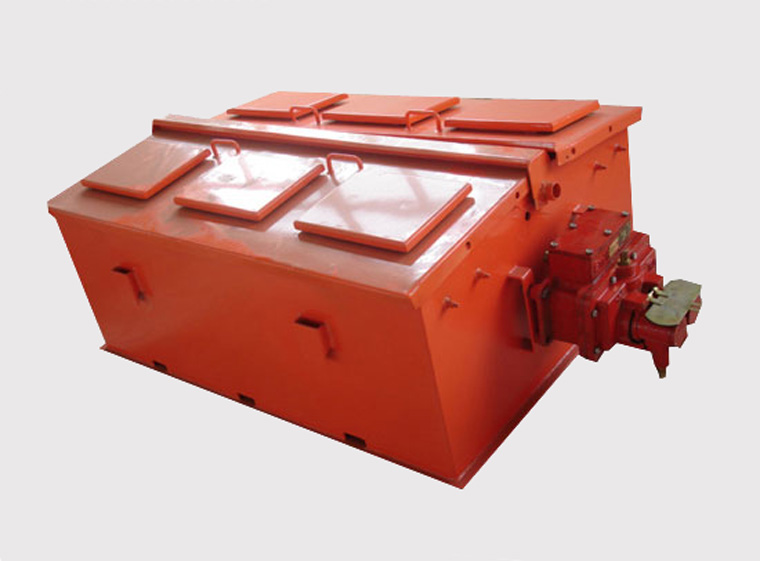

Routine Maintenance Content of Explosion-proof Mine Battery Locomotive Power Supply Unit

About Explosion-proof special type battery mine locomotive daily maintenance, except for including general items, should also check the following items of power supply unit :

(1) Check the battery cables and the pole welding fracture, melting;

(2) Check the rubber insulating sleeve for damage, whether the pole welding parts and live parts exposed;

(3) Check whether the batteries short circuit;

(4) Check the tank for damage and acid leakage, special working bolt have missing or damaged, whether the seat cap off, battery sealant for cracks and acid leak;

(5) once a week, check the leakage current, the value must not exceed the following table requirements; (6) Check the power plug connector is intact;

(7) Check whether the battery box cover for severely deformed.

Routine maintenance and inspection work of explosion-proof mine locomotive power supply unit must be in the charging chamber, the power supply unit upper cover must open in the charged indoors, check the following contents:

(1) battery pole can not be reversed, the distance between the pole not less than 35m m, the distance between pole cable exposed portion and the frame leakage should not less than 10 m m;

(2) the storage battery insulated enclosure resistance should not less than 0.5 M Ω;

(3) the storage battery insulated enclosure current must not be greater than the requirements in Table 4-1, When the battery electrolyte overflows, rinse with fresh water in the tank, discharge purification water with an acid vent valve.