Basic Knowledge of Railway Steel Rails

General rail, refers to the track laying of railway lines, special line, bend and tunnel. Among them, the standard rail length contains 12.50 meters and 25.00 meters two kinds, the laying curve track, has shorter length, 12.46 meters, 12.42 meters and 24.96 meters, 24.92 meters and several other, the general rail specifications for 38,43,45 , 50, 60 (kg / m).

Crane track is used for crane carts and small cars with special section rail, also known as the crane rail, the standard length of 9,9.5,10,10.5,11,11.5,12,12.5 eight kinds. Common specifications for the QU70, QU80, QU100, QU120, the numbers refer to the rail head width.

Rails need to withstand the pressure of locomotive, friction and impact load, requires a sufficient strength, hardness and toughness, high quality requirements, must test its mechanical properties, and low magnification test and drop hammer test.

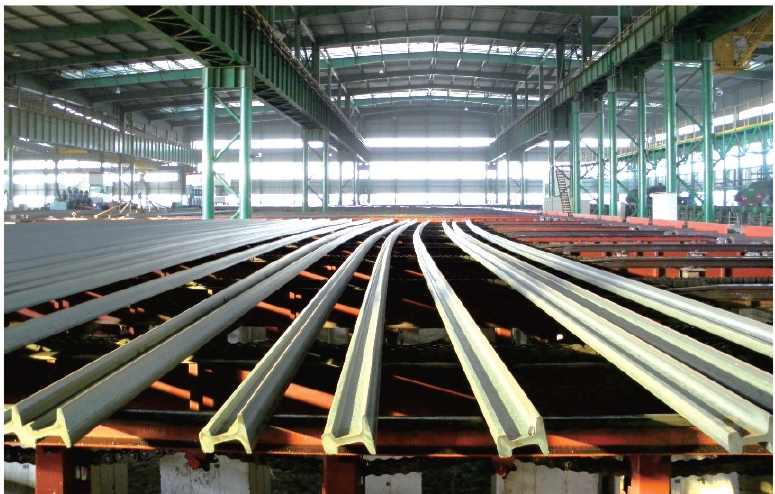

The basic load-bearing structure of railway track is used to guide locomotive vehicles to travel and distribute the load to sleeper, track bed and subgrade. At the same time, it provides the minimum resistance contact surface for wheel rolling. The rails are required to have sufficient load carrying capacity, bending strength, fracture toughness, stability and corrosion resistance. 80 years of the 20th century, the world’s railways, with the exception of the British part of the railway laying double-headed rail, the laying of I-shaped cross-section rails. It consists of rail head, waist and rail end three parts.

Usage of railway steel rails

Heavy-duty steel rails are suitable for heavy-duty, high-speed vehicles; light rails are used for smaller railways and stations. Of large-capacity railway laying heavy duty rails, can reduce maintenance costs, and can reduce the traffic resistance, saving fuel. According to the needs of use, the rail should have a certain standard length. China, the Soviet Union and other countries for 25 meters and 12.5 meters; the United States provides 78 feet and 39 feet (equivalent to 23.774 meters and 11.887 meters).

Material of railway steel rails

The strength, abrasion resistance and resistance to impact of rails depends largely on the material of the rail, which depends on the chemical composition of the steel, the microstructure, the production process and the heat treatment quality. The chemical composition of the rail, in addition to iron, but also contains carbon, manganese, silicon, sulfur and phosphorus. High carbon content can increase the strength of the rail, but carbon is too high, will make it lower plasticity and impact toughness. Properly increase the content of manganese and silicon, can increase the strength of the rail, hardness and toughness. Sulfur and phosphorus are harmful impurities, not allowed to exceed the prescribed limits. In addition, the rail by adding an appropriate amount of chromium, nickel, molybdenum, vanadium, titanium or copper and other elements made of alloy steel rail, can improve the quality of the rail. China since the 70’s has been produced with rare earth, low manganese, silicon and titanium, copper and other low alloy rail. In order to improve the anti-wear performance of the rail end part, to prevent the indentation, to ensure uniform wear and tear of the rail length, usually at both ends of the rail surface quenching in order to improve its hardness; full-length quenching, rail use better.=