What are the classification of rail tamping machine?

There are several types of rail tamping machine as necessary equipment for railway maintenance. Let us take a look at the categories of rail tamping machines.

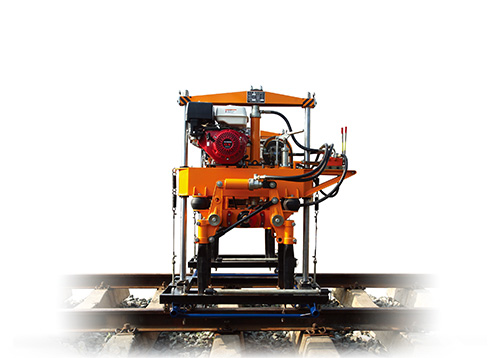

1. Hydraulic rail tamping machine Hydraulic tamping machine double guide column frame structure, single cylinder lifting mode. It is driven by a diesel engine or a motor; it consists of a gear pump, a manual pump, a reversing valve, a vibrating disc, a pick pick, a lifting cylinder and a clamping cylinder. Its working performance can fully meet the needs of line maintenance operations, and it is also suitable for tamping operations for new lines and tamping operations after screening.

2. Internal combustion rail tamping machine is a small road maintenance machine suitable for railway track bed maintenance, mainly used for tamping of ballast track bed. It has a novel design and compact structure. It is a tamping device that can move up and down quickly and is easy to operate. It is especially suitable for turnout tamping operations. This machine is mainly composed of gasoline engine, vibration damping device, transmission shaft, vibrating body and handle. It constitutes an independent and complete hand-held tamping machine. It has neither lengthy cables nor bulky soft shafts. The structure is reasonable and compact and easy to use .

3. Internal combustion soft shaft rail tamping machine This tamping machine is a new type of hand-held railway ballast tamping machine. The characteristic is that the small internal combustion engine is directly connected to the tamping rod through the shock absorbing device, the structure is novel and practical, the volume is small, the weight is light, and the upper and lower lanes are very convenient. It is especially suitable for the maintenance and tamping of the speed-up line using the train gap.

4. The electric rail tamping machine is composed of a control device, a vibration reduction device, a vibration source, and a pick plate. The vibration motor casing is made of aluminum alloy precision casting, which has good heat dissipation. The handle and the vibration source are connected by elastic rubber, and the fan-shaped clamp can adjust the angle. Its working performance can fully meet the tamping operation of the line and the tamping operation after cleaning.